The Advantages of Multicore Cables Over Single Core in Power Transmission

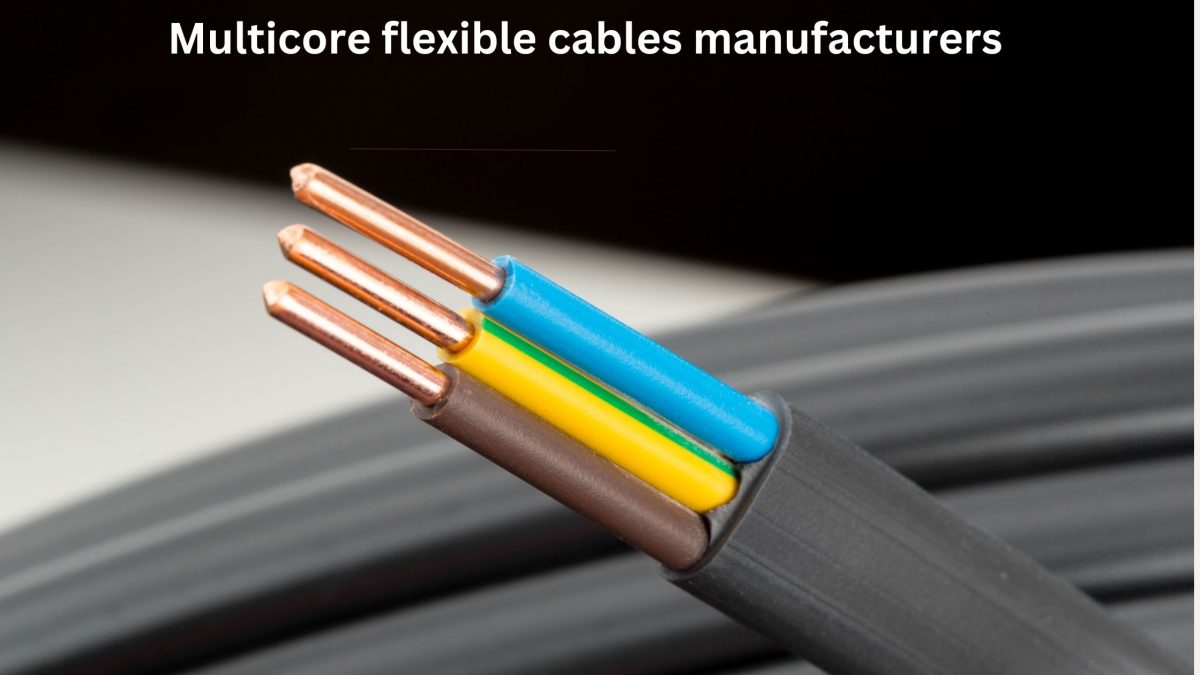

In the present age technology is proceeding at an unparalleled pace, the request for well-organized and consistent electrical solutions is not been so superior. Enter multicore flexible cables a genius of engineering that mixes versatility with performance. These tough cables, constructed with multiple conductive cores, are created to manage complex electrical systems with simplicity.

What is Multi Core Rubber Cable?

A Multi Core Rubber Cable is a kind of cable that typically has a black outer sheath made of rubber and has many conductors inside of it. The rubber offers a protective coating that is resistant to abrasion, corrosion, and water, and it also provides a waterproof covering for an insulated electric line. Rubber cable with five cores is used in a variety of applications because to its high stretch ratio, wide toughness, and capacity to be waterproof. The commercial industries are dominated by rubber cables, which have the same characteristics as rubber and are hence successful.

The use of three-core rubber cable, which is both effective and non-toxic, results in increased productivity and profitability for businesses. Since these rubber cables with four cores do not contain any harmful substances, they are safe for use in the food and beverage sector. In addition to being water-resistant, rubber cable with five cores is also resistant to steam and hot water from the environment.

Multicore flexible cables manufacturers has the most extensive selection of rubber cables that are now accessible. Rubber cables such as H05RN-F, H05RR-F, H07ZZF, H01N2-D, NSHXAFO, H07RN8-F, HO7RN-F, NSSHOU, and NSGAFOU are included in the list of popular rubber cables that may be purchased from them with relative ease. The H05RR-F cable is the encased rubber cable that is the lightest in weight and is used for applications that are straightforward. Complex applications that are exposed to a significant amount of strain and stress are where the H07RN-F finds its application.

Multicore rubber cables and single core cables

Cables with a single core and cables with several cores each have their own unique thermal, electrical, and mechanical characteristics, which may either provide benefits or drawbacks.

Here are some of the most significant things to consider.

1. In situations when large currents are present, the cooling and cost of single-core cables are superior to those of multi-core cables.

2. Due to the lowest possible inductivity between the conductors of the three phases, there is less voltage drop at (long) multi-core cables for enormous start-up currents of induction motors. This is especially true for long cables.

3. In the event of a short circuit, there may be even larger currents that cause single core cables to jump if they are not packed in the appropriate manner, but multi-core cables are unable to jump through the short circuit.

4. On the other hand, single-core cables in conduits are considerably simpler to manage than multi-core cables when dealing with relatively low currents in residential settings. The cross-section area of these cables is around one square millimeter.

Understanding Single Core vs. Multicore Cables

- When we talk about power transmission, selecting the correct type of wire from Multicore flexible cables manufacturers is crucial for efficiency and dependability. The difference between single core and multicore cables is important, as it offers various purposes and comes with its own set of benefits and difficulties.

- Single core cables, as the name suggests, contain of a single conductor, typically made of copper or aluminum, which is surrounded by an insulating layer. These are called for its simplicity and are often used in apps where the transmission distance is short, like the residential wiring or concerning individual appliances to a power source.

- On the other hand, multicore cables feature numerous conductors bundled together in the single sheath. This design lets for superior flexibility and competence in power transmission, creating it multicore cables mainly suitable for more difficult installations. Every core could have separate current, which aids distribute the load more consistently.

- Lastly, consider the permanency and durability of multicore cables. They are planned to survive many environmental factors, which means less maintenance prices and few replacements over the epoch of the installation.

Conclusion

Understanding the differences among single core and multicore cables is important for making informed decisions regarding power transmission. By identifying the distinct pros of multicore cables, you can unlock greater adeptness and trustworthiness, certifying that your electrical systems function optimally and sustainably.