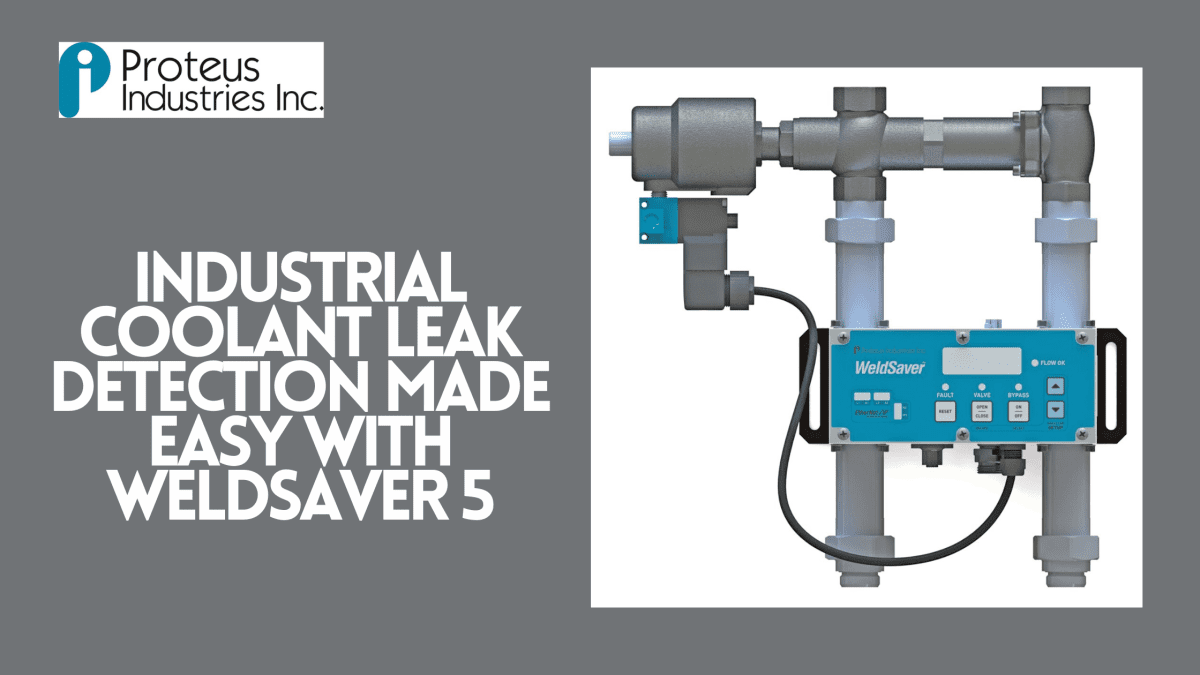

In modern industrial settings, equipment must operate at peak performance due to the use of cooling systems. However, when leaks occur, they can lead to significant downtime, equipment damage, and even safety hazards. Proper coolant leak detection is vital to maintaining the health and efficiency of these systems. The WeldSaver 5 by Proteus Industries offers a comprehensive solution to address these challenges, delivering precise and real-time coolant leak detection that keeps operations running smoothly and efficiently.

Key Features of WeldSaver 5 for Coolant Leak Detection

The WeldSaver 5 from Proteus Industries has several new features that distinguish it as the leading solution for gas leak detection in industrial environments. One of the most popular features is the smart water alarm that provides heating flow and temperature monitoring. This continuous monitoring can detect deviations from normal operating parameters and generate alerts that allow operators to react quickly.

The WeldSaver 5 notifies water sensors and can automatically stop coolant flow when there is a leak. This automatic shutoff feature is crucial in preventing the spread of coolant leaks, which can otherwise damage equipment and cause unplanned downtime. By stopping the flow of coolant within seconds of detecting a leak, the system effectively protects expensive machinery and reduces maintenance costs.

The WeldSaver 5 also integrates seamlessly with industrial control systems using industry-standard interfaces like EtherNet/IP™ and PROFINET®. This integration allows for easy communication between the coolant leak detection system and other critical components, such as robots and weld controllers, ensuring that all aspects of the production process are in sync and safeguarded against coolant leaks.

How WeldSaver 5 Simplifies Coolant Management

Managing coolant in industrial systems involves more than just detecting leaks; it requires continuous monitoring to ensure that the system operates within the given parameters. The WeldSaver 5 simplifies this process by continuously monitoring both the flow and temperature of coolant, providing real-time data to operators via a browser-based user interface or a local display. This ensures that any potential issues with the coolant system are identified before they escalate into major problems.

One of the new innovations in the WeldSaver 5 is the optional eVac™ Coolant Retraction Module. This feature prevents coolant from being expelled during cap changes or cap loss, further protecting equipment from damage. By redirecting coolant flow during these critical moments, the WeldSaver 5 minimizes the risk of spills or leaks that could disrupt the production process.

Overall, the WeldSaver 5 makes coolant management easier and more efficient by offering continuous monitoring, automatic leak detection, and quick response times. Its ability to shut off coolant flow within seconds of detecting a leak ensures that equipment is protected and downtime is minimized, resulting in improved operational efficiency for industrial users.

Applications of WeldSaver 5 Across Industrial Sectors

The WeldSaver 5 is designed to meet the rigorous demands of various industrial sectors that rely on coolant systems, particularly in robotic welding applications.

In robotic welding systems, maintaining adequate cooling is curical to prevent overheating and damage to the welding equipment. The WeldSaver 5 not only detects leaks but also monitors coolant flow to ensure that the welding process is optimized. Its ability to communicate with other industrial systems, such as PLCs and weld controllers, makes it a valuable asset in automated production environments.

Challenges of Industrial Coolant Leak Detection

Industrial environments, especially those involving robotic welding systems, face unique challenges when it comes to coolant management. A small leak in the system can cause serious problems that can affect production and cost. Additionally, leaks can pose safety risks, as coolant may cause slippery surfaces or damage nearby sensitive components.

Traditional methods of leak detection often fall short in terms of accuracy and speed, leaving industrial operators vulnerable to the risks associated with coolant system failures. Slow detection can mean that equipment continues to operate with insufficient cooling, leading to overheating, wear, and eventual damage. To avoid these issues, manufacturers require a coolant leak detection system that not only detects leaks quickly but also responds immediately to shut off the flow and prevent further damage. This is where the WeldSaver 5 excels.

Efficiency, Safety, and Cost Savings with WeldSaver 5

One of the key advantages of the WeldSaver 5 is its ability to deliver significant cost savings and operational efficiency to industrial users. By detecting coolant leaks in real-time and shutting off the flow automatically, the system minimizes the risk of equipment damage and reduces the need for costly repairs. This fast response also helps avoid unplanned downtime, ensuring that production schedules remain on track.

In addition to its cost-saving benefits, the WeldSaver 5 enhances safety in industrial environments by preventing coolant spills and leaks that could lead to accidents. Smart water sensor alerts ensure potential problems are detected and resolved before they endanger personnel or equipment.

The system’s seamless integration with industrial control systems also contributes to overall efficiency, allowing operators to monitor and manage coolant systems remotely via the browser-based interface. This centralized control and monitoring capability simplifies the management of coolant systems and ensures that potential problems are dealt with swiftly and effectively.

Conclusion

The WeldSaver 5 offers a comprehensive solution for coolant leak detection in industrial environments, providing real-time monitoring, automatic shutoff capabilities, and seamless integration with other industrial systems. Its smart water sensor alarms and fast response times make it a valuable tool for preventing equipment damage and minimizing downtime. Industries that rely on robotic welding systems and other automated processes can benefit from the WeldSaver 5’s advanced features, ensuring that their operations remain safe, efficient, and cost-effective.

For more information on the WeldSaver 5 and how it can help your industrial operations, visit Proteus Industries, the leader in innovative coolant management solutions.